Modern Projects and Efficiency Challenges

This article introduce a new methodological approach to project management in machinery — the Physical Hierarchy Assembly State Interface (PHASI).

The goal is to show how physical hierarchy can become a practical interface for readiness, coordination, and measurable project performance.

A recent survey conducted by McKinsey among executives of megaprojects shoed that, on average, projects exceed their budgets and schedules by 30–45%. McKinsey suggests that a high degree of complexity is one of the key causes.

However, even in project-oriented fields of mechanical engineering, where budgets rarely exceed a few million, planned performance and schedule targets are often not achieved.

Among the factors influencing reduced productivity, for example, the Stiftung für den Maschinenbau, den Anlagenbau und die Informationstechnik (PDF report) identifies the following main causes:

- Non-standardized processes

- Lack of data consistency between departments

- High coordination effort

- Insufficient project and interface management

Modern digital infrastructure — ERP, PLM, or project management systems — does not provide the so-called cross-departmental interface management information necessary for transparency between departments, execution teams, and top management.

Therefore, data from the above heterogeneous systems is still collected and processed manually — using Excel, SQL, and similar tools.

For megaprojects, the use of Digital Control Towers has become a solution (Link ). However, for mechanical engineering, such digital systems are generally not applicable — primarily due to the required investment scale.

PHASI Methodology (Physical Hierarchy Assembly State Interface)

To address the challenge of meeting planned performance and schedule targets in mechanical engineering, the PHASI — Physical Hierarchy Assembly State Interface methodology is proposed.

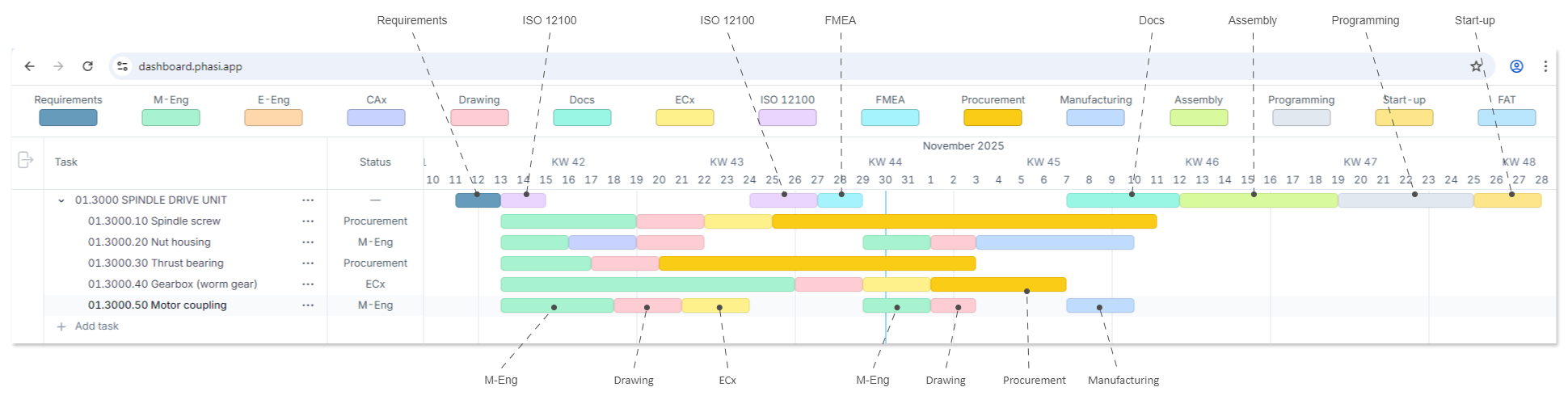

Its essence lies in the fact that the physical hierarchy of a product (assembly, subassembly, component) becomes the main interface for project state management.

In other words, the project is viewed not as a set of time-based phases, but as a hierarchical product structure, in which each unit has its own status (state) over time, reflecting its position in the process of design, procurement, production, or assembly:

The corresponding phases of the PEP process thus act as attributes of the physical structure’s elements, rather than abstract temporal stages:

| Attach to Assemblies | Attach to Components |

|---|---|

| Requirements | M-Eng |

| Docs | E-Eng |

| ISO 12100 | CAx |

| FMEA | Drawing |

| Assembly | ECx |

| Programming | Procurement |

| Start-up | Manufacturing |

| FAT | — |

This approach enables management not of time, but of the state of the product, making the development and production process more visual and interconnected at all levels.

It is important to optimally structure the product so that the distribution of state attributes is consistent throughout the entire product hierarchy — from assemblies down to individual parts.

How the PHASI Approach Solves Productivity Issues

Non-standardized processes

In reality, it is often impossible to fully adhere to a standardized design approach.

Reasons include the lack of engineering or design personnel, insufficient qualification, and temporary factors caused by communication issues — both with the customer and internally between departments, such as design (who creates) and sales (who calculates).

The PHASI-methodology does not enforce formal standardization but makes the project structure transparent and visual.

The distribution of phases (state attributes) within the physical hierarchy of the product eliminates misunderstandings regarding deadlines and priorities between the sales and design departments.

Lack of data consistency between departments

The transparency of the PHASI structure allows all project participants to see the current states of each assembly and component.

This ensures natural data consistency between departments, since information about changes or schedule shifts is displayed directly within the physical hierarchy of the product, rather than in external tables or reports.

One example of effective use of the Phasi-Dashboard is during a shopfloor meeting — when it is important to assess the overall project situation without going into detail.

High coordination effort

Bureaucratic delays are most often caused by a lack of reliable information.

PHASI eliminates this issue because requirements and statuses coming from customers, suppliers, or internal teams are integrated directly into the physical hierarchy interface.

As a result, the respective departments immediately see bottlenecks and can prioritize coordination without unnecessary communication cycles.

For example, during Engineering Change Management (ECM), it becomes transparent and clear what lies behind each change — including how long it will take.

Insufficient project and interface management

PHASI creates a unified interaction space between departments — from design to production.

This physically based interface coordination ensures transparency and alignment of actions among all participants.

Combined with classical project management, PHASI establishes a balance between technical, organizational, and economic aspects of successful project execution.

Conclusion

The Physical Hierarchy Assembly State Interface (PHASI) methodology offers a new perspective on project management in machinery.

It integrates the engineering structure of a product with project state management into a single system, where each component becomes a controllable element.

Thus, PHASI provides the foundation for real, not formal project management — with transparency, predictability, and strong alignment among all participants in the process.

Written by Yevgen Yeshchenko — 2025-11-06